Purpose of hose test or water leakage test (spray) is to provide quality assurance and diagnostic field water check method for installed curtain walls, exterior windows and doors. Spraying water in a…

TTS provides quality assurance and testing service for the exterior wall systems of large buildings. Testing is performed to British, American and other standards. The following are the tests performed…

Torque tightening test is done to check the bolt torque tightening and rotational capacity of bolts by using various calibrated standard ranges of torqueing sensors and fasteners for measuring torque…

Phased array Ultrasonic Testing Specialized Inspection Services Phased arrays are used to detect the image defects including cracks, voids, and pits caused by corrosion. They are used to measure material…

Ultrasonic Testing (UT) is a widely used non-destructive testing (NDT) method that utilizes high-frequency sound waves to inspect the internal structure of materials and detect defects and flaws. It is particularly effective for inspecting welds, forgings, castings, and other manufactured components made of metals and some non-metallic materials.

Radiographic Testing (RT), also known as Radiography or X-ray Testing, is a powerful non-destructive testing (NDT) method used to examine the internal structure of materials and detect flaws and defects that may not be visible on the surface. RT is particularly useful for inspecting thick sections of materials, welds, and complex structures.

Magnetic Particle Testing (MPT), also known as Magnetic Particle Inspection (MPI), is a widely used non-destructive testing (NDT) method for detecting surface and near-surface defects in ferromagnetic materials. This technique is particularly effective in inspecting materials like iron, steel, nickel, and cobalt, where the magnetic field can penetrate and interact with the material’s structure.

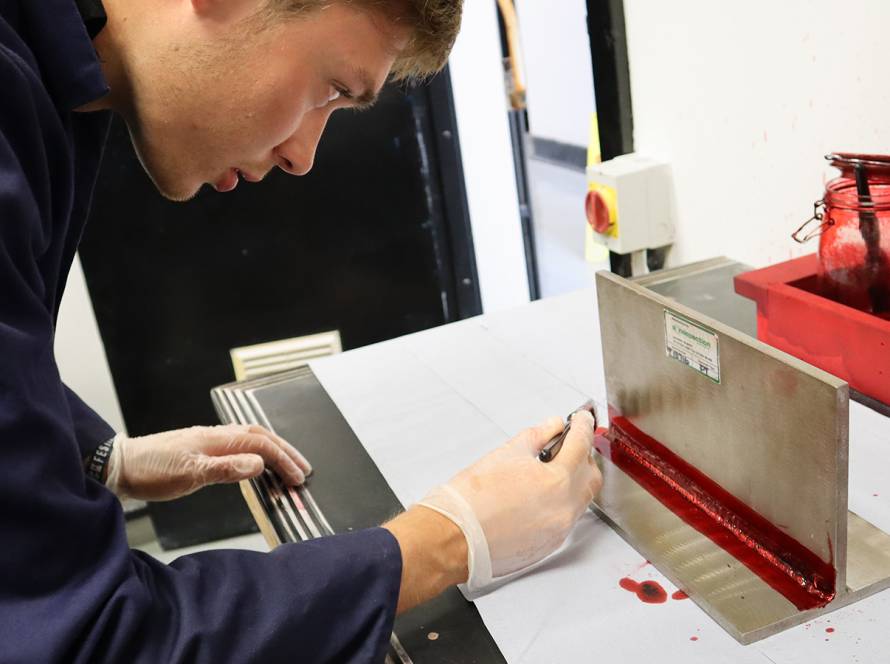

Liquid Penetrant Testing (LPT), also known as Liquid Penetrant Inspection (LPI) or Dye Penetrant Testing (DPT), is a widely used non-destructive testing (NDT) method to detect surface defects and discontinuities in materials. It is particularly effective for inspecting non-porous materials like metals, ceramics, plastics, and some non-metallic materials.

Visual inspection is a non-destructive testing (NDT) method widely used in mechanical testing to examine the surface and external characteristics of a component or material. It involves visually examining the object for any visible defects, such as cracks, corrosion, surface irregularities, or dimensional discrepancies. Visual inspection is often the first step in NDT, as it provides valuable initial information about the condition of the material or part being tested.

The following non destructive examinations services are available in TTS with technical expertise, qualified and experienced technicians and modern equipment’s. These inspection services include, Visual Inspection (VI) Non Destructive Testing…