Product description

The FLOWSIC100 Flare product family is designed for flare gas and steam flow measurements. The product family is characterized by a unique flow-optimized sensor design. This innovative design minimizes flow-generated noise and signal drift when gas velocities are particularly high. Modern signal processing and high-efficiency transducers enable high time resolution for signals and thus

deliver accurate measurements, even at extremely low gas flow rates.

The standard system configuration includes two sender/receiver units or one measuring probe and the MCUP control unit. The MCUP unit is used to input and output signals; to calculate reference values (normalization), molecular weight and mass flow; to record gas volumes; and to provide user-friendly control via the LCD display.

At a glance

• High-resolution measurement and short response time

• Innovative sensor design for very high gas velocities and gas temperatures up to 280 °C

• Optimal signal transmission even under atmospheric pressure

• Detached installation of the control unit up to 1,000 m away

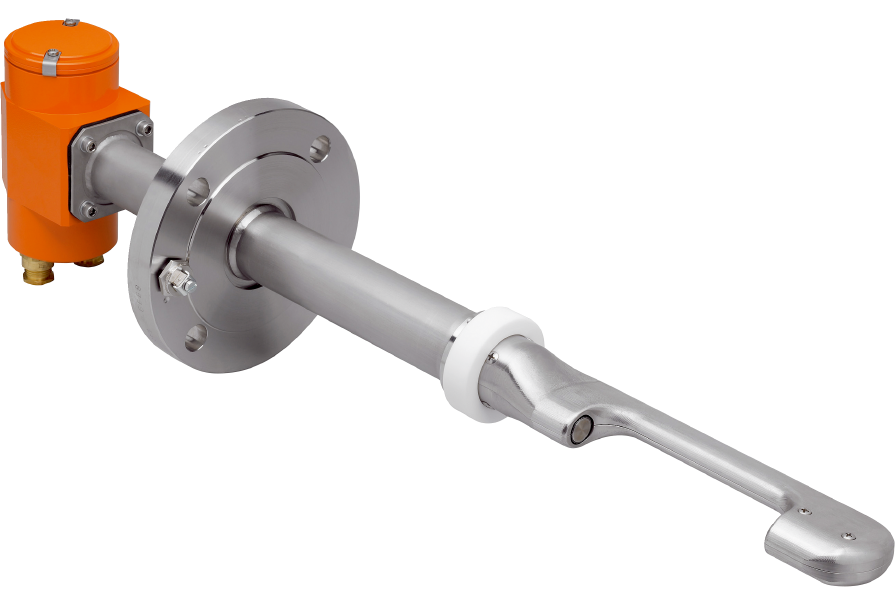

• Single and multi-path configuration, opt. Probe version

• Zero point test in the field according to factory standard

• Control cycle for automatic self-diagnosis / signal optimization

Your benefits

• Reliable process control due to exact measurement near the zero point

• High measurement availability even in the case of emergency shutdowns with gas velocities of up to 120 m/s

• A solution for the measurement of flare gas and steam injection

• Cost savings due to detached installation of the control unit possible in the safe area

• System solution for the control of three different measuring points with a common control unit

• Cost savings due to one-sided installation when using FLOWSIC100 EX-PR probe version